Differences Between Gold Finger Plating and Immersion Gold Plating

The development of AI computing power is driving the PCB market toward high-end, technological upgrading and globalized layout.

Differences Between Gold Finger Plating and Immersion Gold Plating

The main differences between gold finger plating and immersion gold plating lie in aspects such as hardness, solderability, impact on signal transmission, oxidation resistance, cost, and application scenarios. Specifically, the differences are as follows:

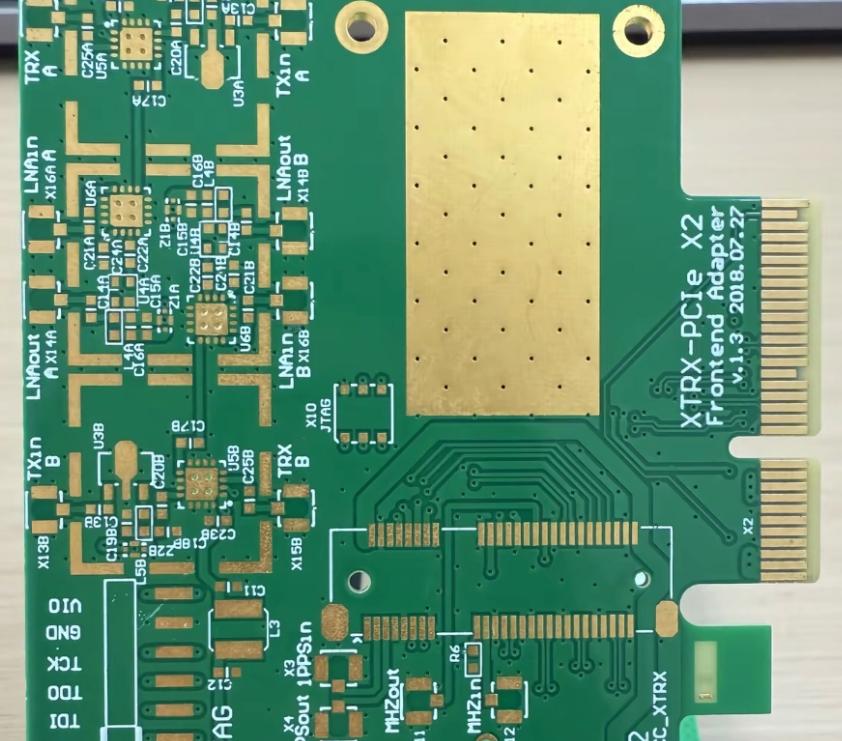

Hardness and Wear Resistance

Gold finger plating produces hard gold, which boasts excellent wear resistance. By contrast, immersion gold plating yields soft gold with poor wear resistance. For this reason, gold finger PCBs typically adopt gold finger plating to ensure the wear resistance and stability of gold fingers during repeated insertion and extraction. SolderabilityImmersion gold is relatively easier to solder compared to gold finger plating, and it does not cause soldering defects. This is because immersion gold has a denser crystal structure that is less prone to oxidation, thereby enhancing solderability.

Impact on Signal Transmission

Immersion gold PCBs have nickel-gold plating only on the pads. According to the skin effect, signals transmit through the copper layer, so immersion gold plating has no negative impact on signal transmission. On the other hand, the gold layer of gold finger plated PCBs may interfere with the transmission of high-frequency signals.

Oxidation Resistance

Immersion gold features a dense crystal structure that resists oxidation effectively. This is crucial for extending the service life of circuit boards and maintaining their excellent electrical performance.

Cost and Application Scenarios

Immersion gold plating generally has a higher cost than gold finger plating. Nevertheless, due to its superior solderability and oxidation resistance, immersion gold plating is more suitable for high-density and ultra-miniature surface mount technologies (SMT). Gold finger plating, however, is better suited for applications requiring high hardness and wear resistance. vironments, gold plating may be a better choice; whereas immersion gold is likely more suitable for circuit boards that demand high-density and ultra-miniature surface-mount technology (SMT) processes.

Related Tags:

Related Articles

UAV PCBs: Bridging Battlefields and Daily Life, Embracing Aspirations for Peace

The development of AI computing power is driving the PCB market toward high-end, technological upgrading and globalized layout.

The Allure of AI Computing Power

The development of AI computing power is driving the PCB market toward high-end, technological upgrading and globalized layout.

The Allure of AI Computing Power

The development of AI computing power is driving the PCB market toward high-end, technological upgrading and globalized layout.